Can You Build With Palm Tree Wood: Proven & Essential

Yes, you absolutely can build with palm tree wood! It’s a surprisingly durable and versatile material for many DIY projects, from furniture to flooring. While different from traditional timber, understanding its unique properties unlocks its potential for unique and beautiful creations.

Have you ever seen a fallen palm tree and wondered if that unique material could be repurposed? Many homeowners and DIY enthusiasts dream of crafting beautiful pieces for their homes, but they often face a puzzling question: can you actually build with palm tree wood? It looks so different from the lumber you see at the hardware store. The good news is, yes, you can! Palm wood offers a distinctive look and surprising strength, perfect for projects wanting a tropical flair. This guide will show you how to work with it, what to expect, and why it’s a rewarding material for your next build.

Understanding Palm Wood: More Than Just a Pretty Trunk

Palm trees, while botanically unique (they’re not true trees but giant herbs!), produce a material that can indeed be used for construction and crafting. Unlike traditional hardwoods or softwoods that have growth rings and distinct grain patterns, palm wood is made up of dense vascular bundles scattered throughout a fibrous matrix. This structure gives it very different characteristics.

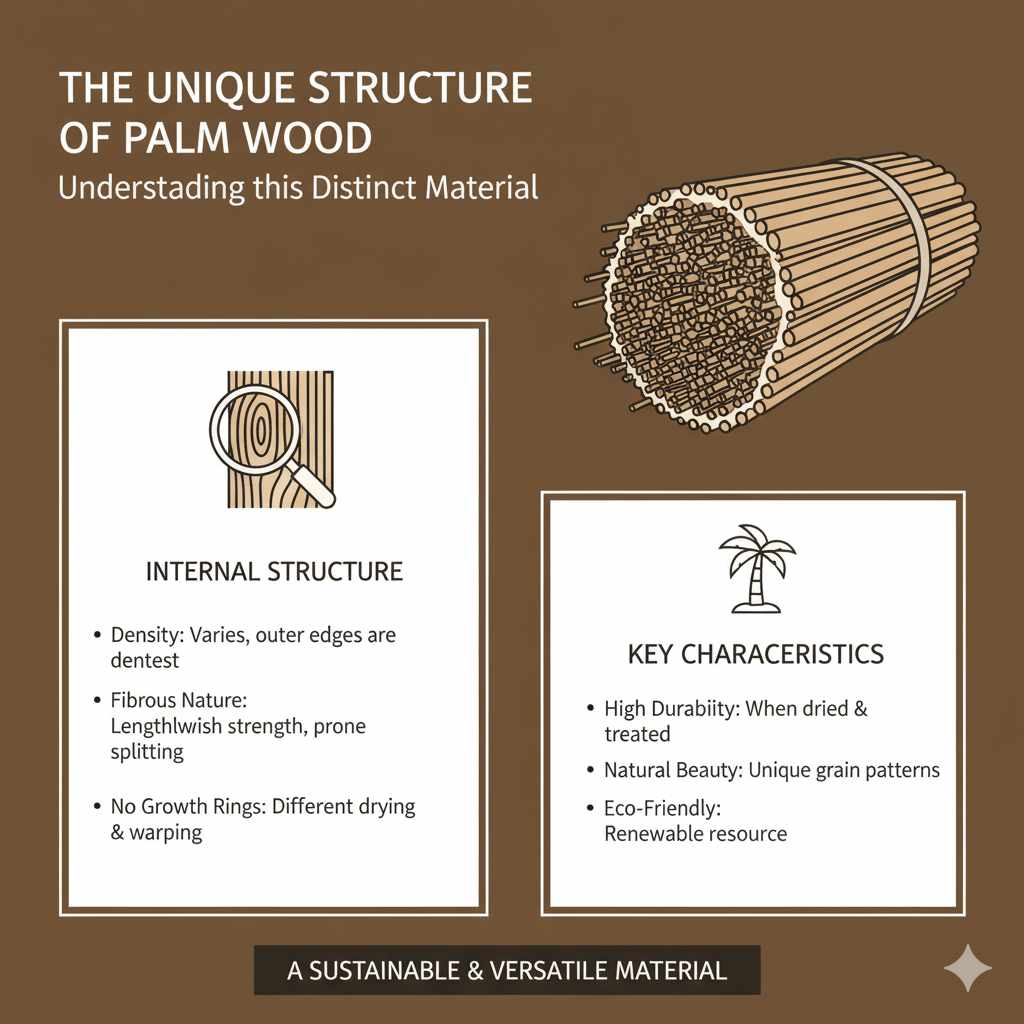

The Unique Structure of Palm Wood

Imagine a bundle of straws packed tightly together. That’s a bit like the internal structure of a palm trunk. These vascular bundles contain the “wood” fibers and are what provide the material’s strength.

Density: The density can vary greatly depending on the palm species and where you take the cut from the trunk. Generally, it’s quite dense, especially towards the outer edges of the trunk.

Fibrous Nature: The fibers run lengthwise, giving it strength in that direction but making it prone to splitting if not handled carefully.

Lack of Growth Rings: This means it behaves differently to drying and warping compared to traditional lumber.

Common Palm Species Used for Wood Projects

Not all palms are created equal when it comes to their wood potential. Some species are much better suited for building than others.

Coconut Palm (Cocos nucifera): Perhaps the most well-known, coconut palm wood is widely used, especially in tropical regions. It’s known for its durability and attractive, often dark, appearance.

Date Palm (Phoenix dactylifera): Another common species, date palm wood is also viable for construction and crafts, though sometimes considered less dense than coconut.

Oil Palm (Elaeis guineensis): Often a byproduct of the palm oil industry, oil palm wood is increasingly being explored for construction applications.

For beginners, focusing on readily available species like coconut palm is often the best starting point.

Is Palm Wood Good for Building? Pros and Cons

Like any building material, palm wood has its advantages and disadvantages. Understanding these will help you decide if it’s the right choice for your project.

The Benefits of Building with Palm Wood

Palm wood offers some fantastic reasons to consider it for your next project.

Unique Aesthetic: It has a distinctive, often striated appearance with dark streaks and a creamy background, giving projects a beautiful, exotic look.

Durability and Strength: When properly dried and treated, palm wood can be very strong and resistant to decay, especially in humid environments. It’s often harder than many traditional woods.

Sustainability: Utilizing fallen palm trees or byproducts from agriculture can be a very sustainable practice, especially in regions where these trees are abundant.

Insect Resistance: Certain species can have natural resistance to termites and other wood-boring insects.

Affordability: In regions where palm trees are plentiful, the raw material can be significantly cheaper than commercially milled lumber.

The Challenges of Working with Palm Wood

It’s not all smooth sailing, and there are challenges you’ll need to be prepared for.

Difficult Milling and Cutting: The fibrous and dense nature can be tough on saw blades and tools. It requires sharp, durable blades and can generate a lot of dust.

Drying and Stability: Properly drying palm wood is crucial to prevent cracking and warping. Without careful drying, it can become unstable. Traditional kiln-drying methods may not be ideal.

Limited Availability: Outside of tropical regions, sourcing good quality palm wood can be difficult and expensive.

Gluing and Finishing: The fibrous texture can sometimes make achieving a perfectly smooth surface for glue-ups or finishes a bit trickier. It can also soak up finishes quickly.

Variability: The strength and density can vary significantly even within the same species, making consistency a challenge.

Here’s a quick comparison of palm wood to some common hardwoods:

| Property | Palm Wood (Varies by species) | Oak | Pine |

|---|---|---|---|

| Hardness (Janka) | 1200-3000+ PSI (Highly variable) | 1290 PSI | 380-870 PSI |

| Density (Lbs/cu ft) | 30-50+ | 45 | 25-35 |

| Grain Pattern | Fibrous, striated | Pronounced, open grain | Closed grain, knots common |

| Workability | Can be tough, prone to splintering | Good, but can dull tools | Easy, but can dent |

| Stability | Requires careful drying | Moderately stable | Prone to shrinking/swelling |

Note: Janka hardness ratings for palm wood are highly generalized due to the wide variations in species and location within the trunk. Always test a sample if possible.

Getting Started: Preparing Palm Wood for Building

Before you can start building, you need to properly prepare your palm wood. This is arguably the most critical step for ensuring a successful project.

Harvesting and Selecting Your Palm Wood

If you have access to fallen palm trees, selecting the right part of the trunk is important.

Outer Sections are Denser: The outer layers of the palm trunk are typically much denser and stronger than the inner core. You’ll want to use wood from these outer “slabs” or “beams” if you’re milling your own.

Mature Trees: Wood from mature trees generally has better structural integrity.

Avoid Rot and Damage: Inspect any harvested wood for signs of rot, insect infestation, or significant cracks before you commit to using it.

Milling Palm Wood: Tools and Techniques

Milling your own palm wood can be challenging but rewarding. The fibrous nature requires specific considerations.

1. Safety First: Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and a dust mask. Palm wood dust can be very irritating.

2. Sharp Blades are Essential: Use high-quality, sharp carbide-tipped saw blades designed for hardwoods or even specialized blades for tropical woods. Dull blades will bind, overheat, and lead to tear-out.

3. Slow and Steady: Feed the wood through the saw at a consistent, moderate pace. Forcing the cut will only lead to problems.

4. Consider the Grain: While there isn’t “grain” in the traditional sense, the long vascular bundles will influence how the wood cuts. Try to cut across the bundles where possible for a cleaner cut.

5. Milling Options:

Chainsaw Mill: For larger logs, a chainsaw mill attachment can be a good way to get initial slab cuts.

Table Saw/Bandsaw: Once you have manageable sections, a sturdy table saw or bandsaw can be used for ripping and cross-cutting. Be prepared for blades to dull quickly.

Specialized Equipment: For commercial milling, specialized equipment designed for dense, fibrous woods is often used.

Drying Palm Wood: The Key to Stability

Improperly dried palm wood is a recipe for disaster, leading to cracks, splits, and warping.

1. Air Drying (Recommended for Beginners):

Stickering: Stack your cut lumber with stickers (thin strips of wood) between each layer. This allows air to circulate freely.

Location: Stack in a shaded, well-ventilated area, off the ground. Protect it from direct sun and rain.

Patience: Air drying can take many months, even up to a year or more, depending on the thickness of the wood and local humidity.

Sealing Ends: To minimize end checks (cracks), you can seal the ends of your boards with wax or a commercial end-grain sealer.

2. Kiln Drying (Faster but Complex):

Kiln drying can speed up the process significantly but requires specialized equipment and knowledge. Conventional kilns can sometimes cause issues with palm wood due to its unique structure potentially leading to collapse or honeycombing. Low-temperature, controlled drying is usually preferred.

Essential Tools for Working with Palm Wood

You don’t need a professional workshop, but a few key tools will make your experience much more enjoyable and successful.

Safety Gear: Safety glasses, hearing protection, dust mask.

Sharp Saws: Good quality circular saw, miter saw, or even a handsaw for smaller pieces. Use blades designed for hardwoods.

Drill: For making pilot holes; palm wood can split easily otherwise.

Sanding Tools: Random orbital sander with various grits (from 80 to 220).

Hand Planes (Optional but useful): For fine-tuning surfaces if milling isn’t perfectly flat.

Wood Chisel: For cleaning up joints or removing small imperfections.

Measuring Tools: Tape measure, square.

Clamps: Essential for gluing up projects.

Building with Palm Wood: Techniques and Project Ideas

Once your palm wood is properly prepared, you can start building! The techniques are similar to traditional woodworking, but with a few important considerations.

Joining Palm Wood

Because of its fibrous nature and tendency to split, certain joining methods work better than others.

Screws: Always pre-drill pilot holes that are slightly smaller than the screw shank. This prevents splitting, especially near edges. Use good quality screws.

Nails: Can be used but are more prone to causing splitting than screws. Pre-drilling is also recommended. Galvanized or stainless steel nails are best for outdoor projects.

Glue: Wood glue (PVA) works well. Ensure good surface contact and ample clamping pressure. For outdoor projects, use a waterproof exterior-grade glue.

Dovetails and Mortise & Tenon: These traditional joinery methods can be used, but they require a high degree of precision, very sharp tools, and careful execution due to the wood’s tendency to splinter. For beginners, simpler joinery is often best.

Finishing Palm Wood

The unique texture of palm wood lends itself to beautiful finishes.

Sanding: Start with a coarser grit (e.g., 80-100) to flatten the surface and remove milling marks. Progress through finer grits (e.g., 150, 220) for a smooth finish. You might find you need to de-nib (lightly sand with 220 grit after applying a pre-finish sander) if the fibers raise.

Sealers: A good quality wood sealer can help even out the finish absorption.

Oils: Penetrating oils like tung oil or linseed oil can bring out the natural beauty and color of the wood. They often require multiple coats.

Varnishes and Lacquers: For durable protection, especially on outdoor furniture or high-traffic surfaces, multiple coats of marine-grade varnish or polyurethane are excellent.

Staining: While you can stain palm wood, its natural variation can lead to blotchy results. Many prefer to let the natural colors shine. If you do stain, use a pre-stain conditioner.

Beginner-Friendly Palm Wood Projects

Start small to get a feel for how the wood behaves.

1. Coasters: A simple project to practice cutting, sanding, and finishing. Seal them well to protect against moisture.

2. Picture Frames: Allows you to practice miter cuts and joinery. The natural patterns of palm wood make for unique frames.

3. Small Decorative Boxes: Teaches basic box construction techniques.

4. Garden Stakes or Labels: Durable and naturally suited for outdoor use.

5. Cutting Boards (with caution): While aesthetically pleasing, ensure you use food-safe finishes and understand that palm wood might be more porous than traditional hardwoods for this application. Thorough sealing and regular maintenance are a must.

Here’s a look at how palm wood might perform in different applications:

| Project Type | Suitability with Palm Wood | Considerations |

|---|---|---|

| Indoor Furniture (Tables, Chairs, Shelves) | Excellent | Requires careful drying and finishing for stability and appearance. |

| Outdoor Furniture & Decor | Very Good | Choose dense species, use waterproof finishes/adhesives, and allow for proper drying. Can be naturally rot-resistant. |

| Flooring | Good | Requires specialized milling, installation, and finishing. Can be very attractive but may require more maintenance than traditional flooring. See examples from the Forest Products Laboratory on tropical woods. |

| Cabinetry | Good | Can offer a unique look for cabinet doors or drawer fronts. Requires precise joinery. |

| Small Crafts (Bowls, Utensils) | Fair to Good | Can be challenging due to fiber structure and potential for splintering. Requires very sharp tools and careful finishing, especially for food contact. |

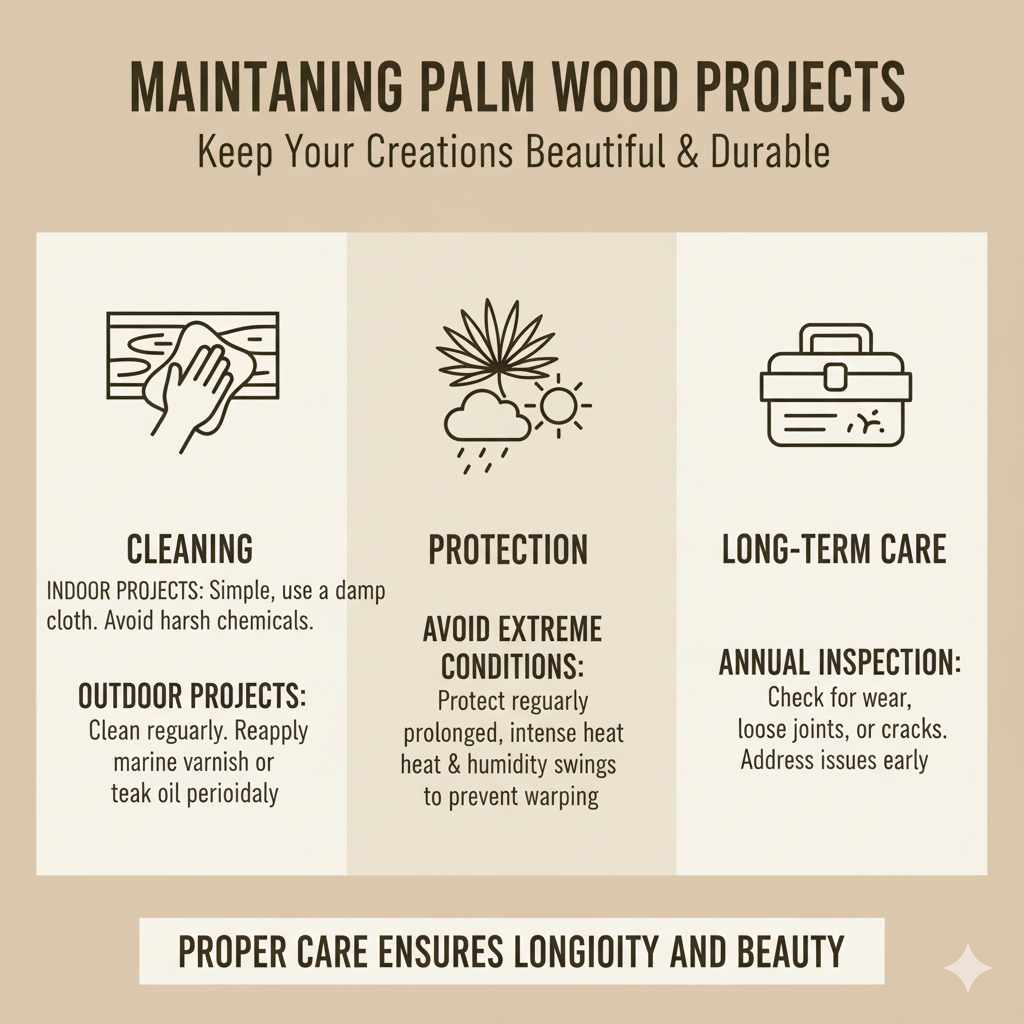

Maintaining Palm Wood Projects

To ensure your creations last, proper care is essential.

Cleaning is Simple: For most indoor projects, a damp cloth is sufficient. Avoid harsh chemicals.

Outdoor Care: Outdoor furniture should be cleaned regularly and may benefit from periodic reapplication of a protective finish (like marine varnish or teak oil) to maintain its appearance and longevity.

Avoid Extreme Conditions: While more stable than some woods if dried properly, prolonged exposure to extreme humidity fluctuations or direct, intense heat can still cause damage.

Frequently Asked Questions (FAQ)

Q1: Is palm wood safe to eat off of?

A1: If you plan to use palm wood for cutting boards or serving surfaces, it’s crucial to use only food-safe finishes and sealants. Ensure the wood itself is free from any natural toxins or treatments. Thorough sealing and regular maintenance are vital to prevent moisture and bacteria absorption. It’s generally less ideal than denser hardwoods like maple for direct food contact.

Q2: What kind of saw blades work best for cutting palm wood?

A2: Because palm wood is very fibrous and dense, it dulls blades quickly. Use high-quality, sharp carbide-tipped blades designed for hardwoods or tropical woods. Consider blades with more teeth for a cleaner cut, but be prepared for slower feed rates.

Q3: How do I prevent palm wood from splitting when screwing or nailing?

A3: Always pre-drill pilot holes! The pilot hole should be slightly smaller than the diameter of the screw or nail you are using. This is especially important when working near the edges of the wood to prevent the fibers from splitting.

Q4: Can I use palm wood outdoors?

A4: Yes, many palm species, particularly coconut palm, are naturally quite durable and resistant to decay and insects, making them suitable for outdoor projects. However, it’s essential to use waterproof exterior-grade glues and finishes for maximum longevity. Proper drying is still critical.

Q5: Will palm wood warp or crack?

A5: Like all wood, palm wood can* warp or crack if not dried properly. The fibrous structure requires careful, slow drying to equalize moisture content and prevent internal stresses from causing damage. Air drying with good ventilation and stickers is often recommended for beginners.

Q6: Where can I buy palm wood?

A6: Availability varies greatly by region. In tropical areas, you might find it from local suppliers, sawmills, or even directly from individuals who have access to fallen palm trees. Outside of these areas, it can be very difficult to source commercially. You might find some specialty wood suppliers online, but be prepared for potentially high shipping costs.

Q7: How much does palm wood cost?

A7: The cost of palm wood is highly dependent on your location and availability. In regions where it’s abundant, it can be very inexpensive, sometimes even free if you can salvage fallen trees. In areas where it needs to be imported, it can become quite expensive, often comparable to or even exceeding the cost of some common hardwoods.

Conclusion: Embrace the Unique Beauty of Palm Wood

Building with palm tree wood is a journey that offers a unique reward. While it presents its own set of challenges, particularly in preparation and milling, the distinctive beauty and surprising durability of the finished product are well worth the effort. For both the adventurous beginner and the seasoned woodworker looking for something new, palm wood opens up a world of creative possibilities. From rustic outdoor furniture to striking indoor accents, projects crafted from this tropical material carry a story and a visual appeal that traditional lumber simply can’t match.

With careful preparation, the right tools, and a willingness to learn its unique characteristics, you can confidently build beautiful, lasting pieces.