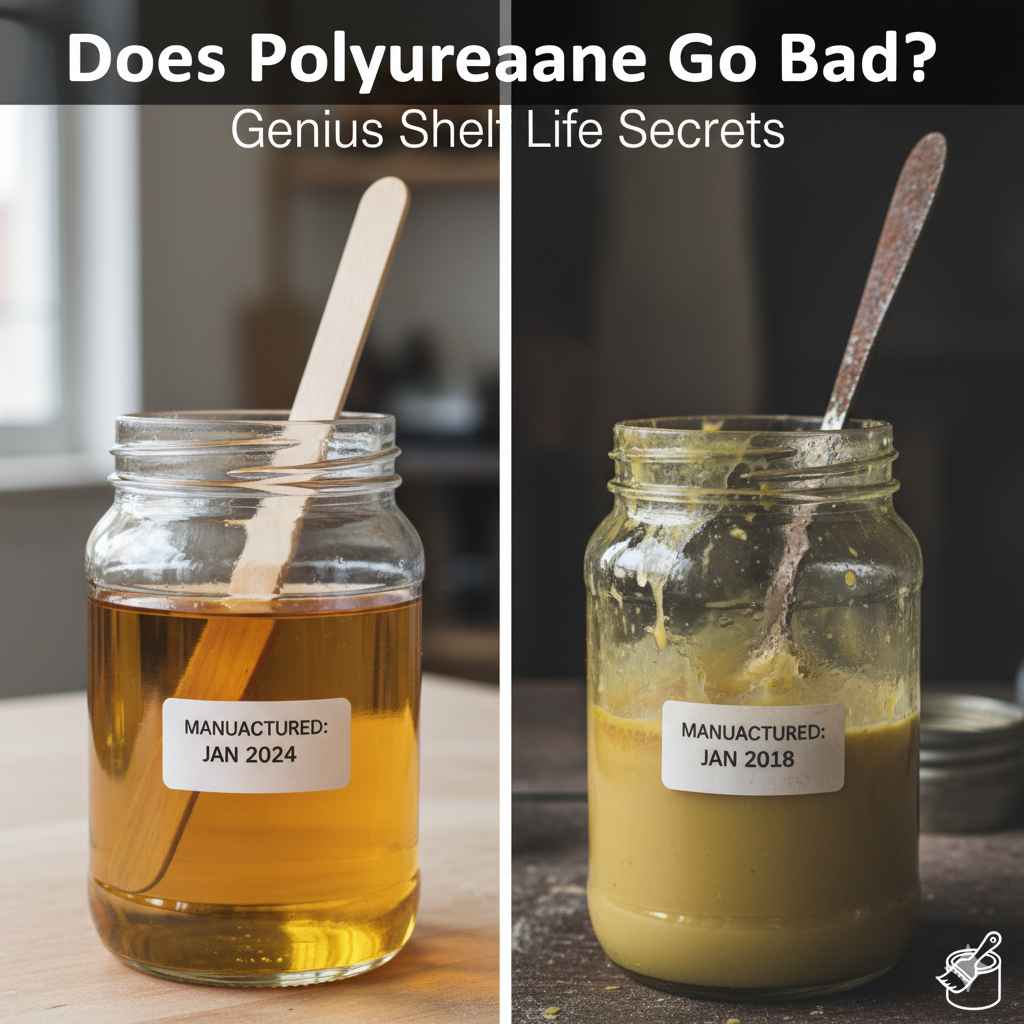

Does Polyurethane Go Bad? Genius Shelf Life Secrets

Yes, polyurethane can go bad, but with proper storage, it can last for several years. Understanding its shelf life and signs of spoilage ensures you get the best results for your woodworking projects and avoid wasted materials.

Hey there, fellow woodworkers and DIYers! Md Meraj here, ready to tackle a question that pops up in many workshops: does polyurethane actually go bad? We’ve all been there, staring at a can of finish, wondering if it’s still good to use or if it’s time to toss it. It can be frustrating to grab an old can, only to find it’s become lumpy, gummy, or just plain useless. But don’t worry! Knowing a few simple secrets about polyurethane’s shelf life can save you time, money, and the headache of a failed project. We’ll dive into how to tell if your polyurethane is still in its prime and how to make sure it stays that way. Get ready to unlock the secrets to keeping your finishes fresh!

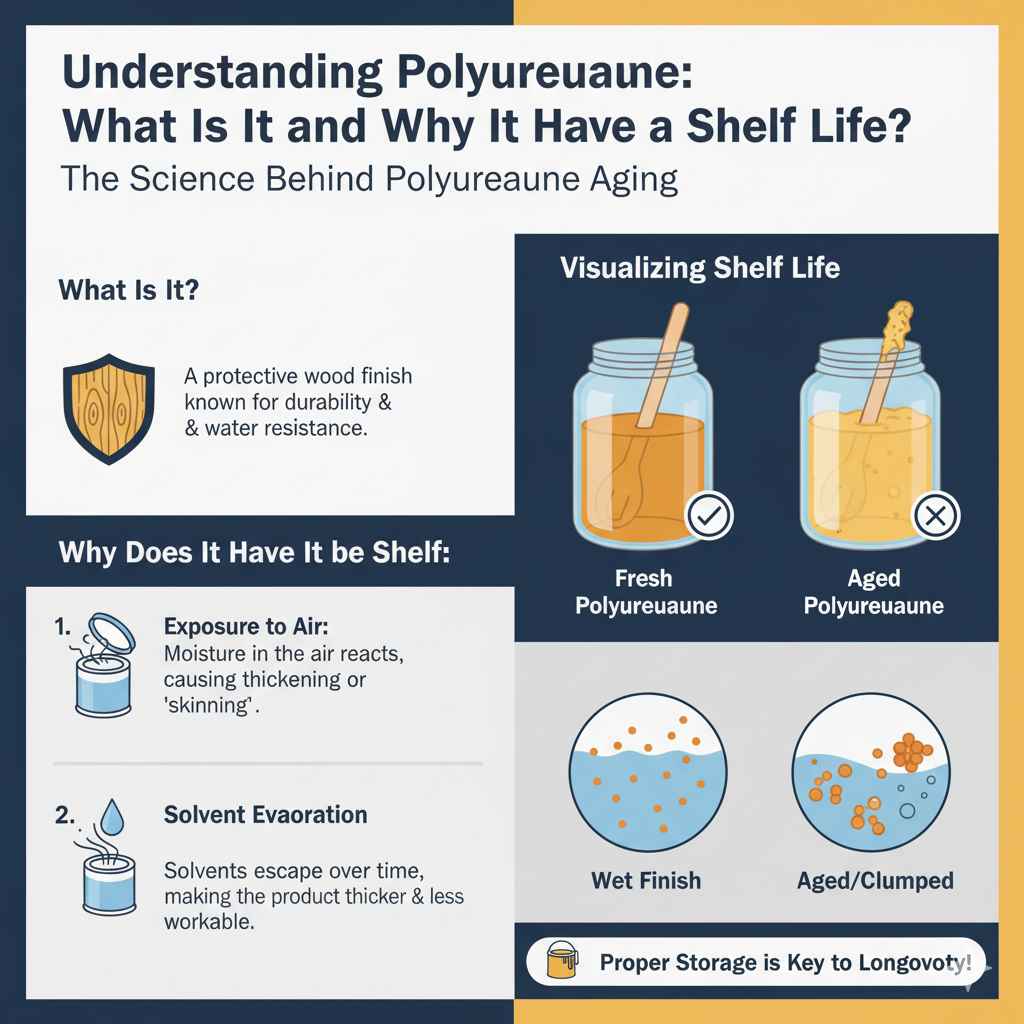

Understanding Polyurethane: What Is It and Why Does It Have a Shelf Life?

Polyurethane is a fantastic finishing product for wood. It’s known for its durability, resistance to water, and ability to protect your wooden surfaces from everyday wear and tear. Whether you’re refinishing a beloved table or building a new piece of furniture, polyurethane is a go-to for a tough, clear coat.

But like many things in life, polyurethane doesn’t last forever. It’s a chemical product, and over time, those chemicals can change. This change is what we call “going bad,” and it affects how well the polyurethane will perform. The main reason for its limited shelf life is its exposure to air and the natural aging process of its ingredients.

The Science Behind Polyurethane Aging

When you open a can of polyurethane, you’re introducing it to air. This exposure can start a slow chemical reaction. Specifically, moisture in the air can react with the polyurethane, causing it to thicken or even skin over. This skin is like a barrier that, if it mixes into the finish, can cause problems when you try to apply it.

Plus, the solvents in polyurethane naturally evaporate over time, even with the lid tightly sealed. As these solvents disappear, the remaining resin becomes more concentrated, leading to a thicker, less workable product. This is why proper sealing and storage are so crucial!

Does Polyurethane Go Bad? The Tell-Tale Signs of Spoilage

So, how can you tell if your polyurethane is past its prime? It’s not always obvious, but there are a few key indicators to look for. Trusting your senses is your best bet here!

Visual Clues: What to Look For

- Skin Formation: This is the most common sign. A thick, rubbery skin on top of the liquid is a clear indicator that some drying has occurred. While you can sometimes carefully remove this skin, if it’s extensive or the liquid underneath is very thick, it’s a bad sign.

- Lumps and Clumps: If you see any solid bits or lumpy masses floating in the liquid, your polyurethane has likely started to break down. These won’t mix out and will ruin your finish.

- Cloudiness: While some water-based polyurethanes might have a slight haze, a significant and unexpected cloudiness in oil-based polyurethane can mean it’s deteriorating.

- Separation: If the liquid has separated into distinct layers that don’t easily mix back together, it’s often a sign of age and instability.

Texture and Consistency: Feeling the Difference

- Excessive Thickness/Gummyness: If the polyurethane is much thicker than usual, almost like syrup or even jelly, it’s likely too old. The solvents have evaporated, leaving a gummy residue.

- Gritty Texture: Even after removing a skin, if the liquid feels gritty when you stir it, it means dried particles have mixed in.

Smell Test: A Pungent Signal

A normal, fresh can of polyurethane has a distinct chemical smell. However, if the smell is unusually strong, acrid, or has a foul odor, it could be a sign that the product has degraded. This is less common but still a possibility.

Polyurethane Shelf Life: How Long Does It Really Last?

The lifespan of polyurethane can vary quite a bit depending on several factors, primarily how it’s stored and the type of polyurethane it is. While manufacturers typically don’t put an exact expiration date on cans, general guidelines exist.

General Shelf Life Estimates

Here’s a breakdown of what you can generally expect:

| Type of Polyurethane | Estimated Shelf Life (Unopened) | Estimated Shelf Life (Opened & Properly Sealed) |

|---|---|---|

| Oil-Based Polyurethane | 3-5 years | 1-2 years |

| Water-Based Polyurethane (Lattices) | 1-2 years | 6 months – 1 year |

| Water-Based Polyurethane (Acrylic) | 2-3 years | 1 year |

Important Note: These are estimates. A can stored in ideal conditions might last longer, while one stored poorly could go bad much sooner. Always check for the signs of spoilage discussed earlier!

Factors Affecting Shelf Life

- Air Exposure: The biggest culprit! Every time you open the can, you let more air in, accelerating the drying and degradation process.

- Temperature Fluctuations: Extreme heat or cold can damage the chemical stability of polyurethane. Freezing and thawing cycles are particularly bad.

- Moisture: High humidity in the storage area can also contribute to degradation.

- Storage Container: The original can is usually designed to seal well, but if it’s rusted or damaged, it won’t protect the contents effectively.

Genius Secrets: How to Properly Store Polyurethane for Maximum Shelf Life

Now for the good stuff! Following these storage tips will significantly extend the life of your polyurethane and ensure it’s ready to use when you are. Think of it as giving your finish the best chance to stay fresh and effective.

The Golden Rules of Storage

When it comes to keeping your polyurethane fresh, it’s all about minimizing air exposure and maintaining a stable environment. Here are the key strategies:

- Clean the Rim: Before sealing an opened can, wipe the rim and the inside of the lid completely dry. Any drips or residue can prevent a tight seal and act as a starting point for skinning.

- Seal It Tight: Ensure the lid is pressed down firmly all the way around. For oil-based polyurethanes, a few gentle taps with a rubber mallet can help create a good seal.

- Use Plastic Wrap: For an extra layer of protection, place a piece of plastic wrap over the can opening before putting the lid back on. This creates an even tighter seal and helps keep air out. This is a simple trick that many pros swear by!

- Store Upright: Always store polyurethane cans upright. This prevents leaks and minimizes the surface area of the liquid exposed to any air that might still be in the can.

- Choose a Stable Environment: Find a cool, dry place with a consistent temperature. A basement workshop or a climate-controlled garage is often ideal. Avoid sheds or areas prone to extreme heat, cold, or humidity.

- Consider an Airtight Container: For opened cans, especially if you don’t think the original lid seals perfectly, consider transferring the polyurethane to a smaller, airtight glass jar or a metal container. Make sure it’s clean and dry, and fill it as much as possible to reduce air space.

Advanced Storage Hack: The Oil Blanket

This is a fantastic trick, especially for oil-based polyurethanes, and one that seasoned woodworkers often use. It helps prevent skinning and oxidation.

- After wiping the rim and sealing the lid tightly on an opened can, gently tilt the can and pour a thin layer of mineral spirits (for oil-based) or clean water (for water-based) over the surface of the polyurethane.

- This creates a barrier that prevents air from reaching the finish.

- When you’re ready to use the polyurethane again, simply pour off this top layer of liquid. You might need to strain it through a fine-mesh sieve or cheesecloth to catch any small skin particles that may have formed. Be sure to discard the mineral spirits or water separately – don’t pour them down the drain!

For more details on best practices for storing wood finishes, resources like Woodsmith Magazine’s storage tips offer very practical advice.

What to Do with Old or Bad Polyurethane

Sometimes, despite your best efforts, polyurethane goes bad. It’s disappointing, but it’s important not to try and use it. Applying old, degraded polyurethane can lead to a number of problems, including:

- A rough, uneven finish

- Poor adhesion

- Yellowing or discoloration

- Brittle coating that chips or cracks easily

- Extended drying times and unpleasant odors

So, what do you do with it? Disposing of old polyurethane requires care. You can’t just pour it down the drain or toss it in the regular trash.

Safe Disposal Methods

- Let it Dry Out: For small amounts, the safest way to dispose of polyurethane is to let it dry out completely. Pour it into a cardboard box or a disposable container lined with newspaper. Place it in a well-ventilated area away from flames or sparks. Once it’s completely hard and solid, you can typically dispose of it with your regular household trash, but it’s always a good idea to check your local waste disposal regulations.

- Local Hazardous Waste Collection: For larger quantities or if you’re unsure, contact your local waste management authority or check for household hazardous waste collection events in your area. They have specific guidelines for disposing of paints, solvents, and other chemicals. The U.S. Environmental Protection Agency (EPA) provides information on hazardous waste management that can help you understand the requirements.

- Recycling Centers: Some recycling centers accept old paint and finishes. It’s worth checking with your local facility.

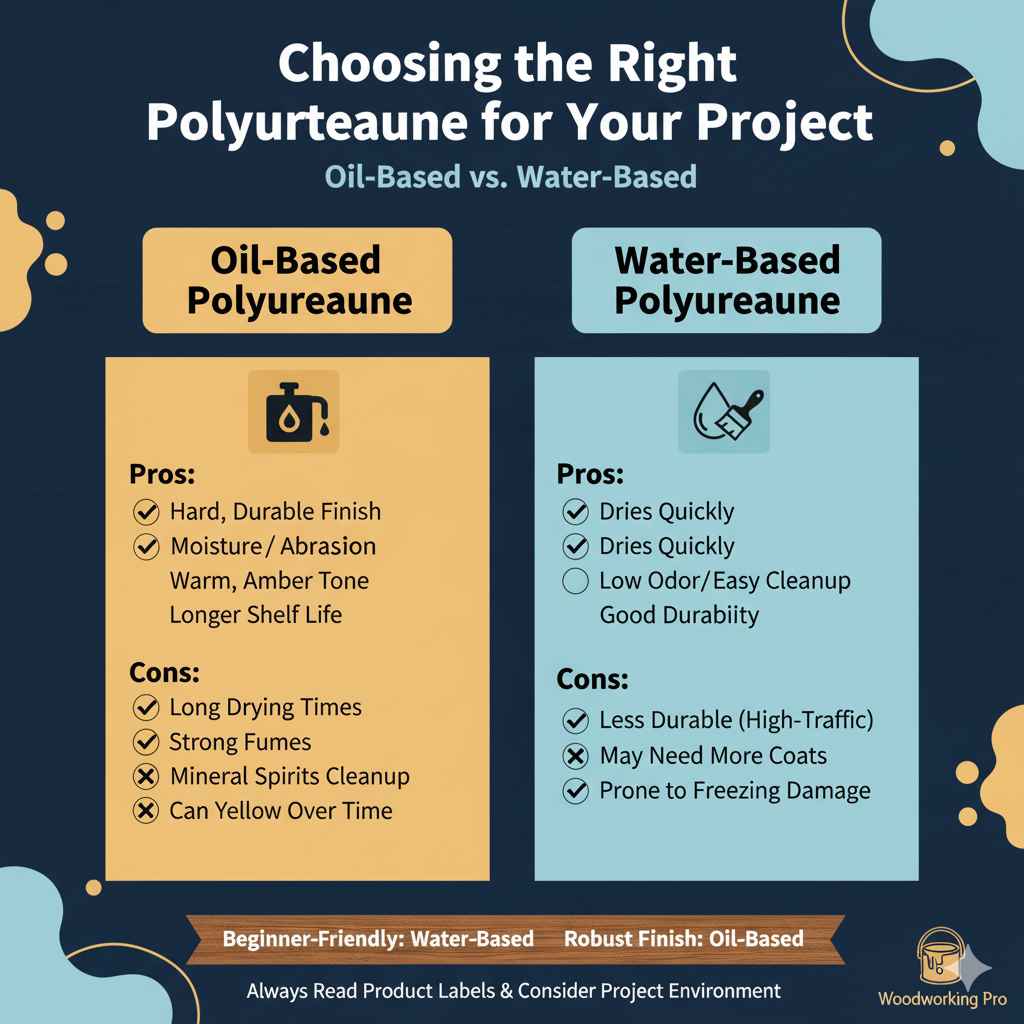

Choosing the Right Polyurethane for Your Project

While we’re talking about shelf life, it’s worth mentioning that choosing the right type of polyurethane for your project can also impact how easy it is to work with and how long it lasts. There are two main types:

Oil-Based Polyurethane

Pros:

- Creates a hard, durable finish.

- Offers excellent moisture and abrasion resistance.

- Has a warm, amber tone that can enhance the wood’s natural color.

- Generally has a longer shelf life than water-based formulas.

Cons:

- Longer drying times.

- Strong fumes (requires good ventilation).

- Requires mineral spirits for cleanup.

- Can yellow over time, which might not be desirable on light-colored woods.

Water-Based Polyurethane (Lattices or Acrylics)

Pros:

- Dries quickly.

- Low odor and easy cleanup with soap and water.

- Dries clear, maintaining the wood’s natural color.

- Good durability, especially modern acrylic formulas.

Cons:

- Can be less durable than oil-based in some high-traffic applications.

- May require more coats for sufficient protection.

- Can be more prone to freezing damage.

For beginners, water-based polyurethanes are often easier to work with due to their quick drying times and simple cleanup. However, oil-based polyurethanes offer a robust finish that can be very forgiving in terms of application. If you’re unsure, read the product label carefully and consider the environment where your project will be used. For more detailed comparisons, resources like Popular Mechanics’ guide can be very informative.

Frequently Asked Questions About Polyurethane Shelf Life

Q1: How can I tell if opened polyurethane is definitely bad?

A1: If you see a thick, rubbery skin, lots of lumps or solid bits, or if the liquid is extremely thick and gloopy, your polyurethane is likely past its prime. A strong, foul odor can also be a bad sign.

Q2: Can I revive old polyurethane?

A2: While you can strain out a thin skin, if the poly is very thick, lumpy, or smells off, it’s best not to try and revive it. Using it can lead to a poor finish. It’s safer to dispose of it properly and buy a fresh can.

Q3: Does polyurethane get thicker as it ages?

A3: Yes, that’s a common sign of aging. The solvents in polyurethane naturally evaporate over time, which makes the remaining product thicker and more viscous. If it’s significantly thicker than when you first bought it, it’s probably going bad.

Q4: What’s the best way to store polyurethane?

A4: Store polyurethane in a cool, dry place with a stable temperature, away from direct sunlight. Always store cans upright, ideally in a well-ventilated but sealed environment like a workshop cabinet. For opened cans, ensure the lid is sealed tightly, and consider using plastic wrap under the lid or a layer of mineral spirits for oil-based types.

Q5: Does the brand of polyurethane affect its shelf life?

A5: While quality can vary, most reputable brands of polyurethane will have similar shelf lives when stored under the same conditions. The storage method is far more critical than the brand itself in determining how long it will last.

Q6: Can refrigerated polyurethane last longer?

A6: Storing polyurethane in the refrigerator is generally not recommended. The fluctuating temperatures of a refrigerator, especially when the door is opened and closed, can be detrimental. A cool, stable temperature, like in a basement, is usually better. Extreme cold can also damage some formulas.

Conclusion: Keeping Your Polyurethane Prime for Perfect Finishes

So, there you have it! Polyurethane doesn’t last forever, but with a little knowledge and care, you can significantly extend its usable life. By understanding the signs of spoilage—looking for skins or lumps, checking the consistency, and even giving it a smell—you can avoid using a bad batch that could ruin your project. Remember those genius storage secrets: clean rims, tight seals, plastic wrap, upright storage, and a stable environment. The oil blanket trick is a lifesaver for those who use oil-based polyants.

By investing a few extra moments in proper storage, you’re not just preserving a product; you’re ensuring the craftsmanship and durability of every piece you finish. This saves you money in the long run and gives you peace of mind knowing your tools are always ready when inspiration strikes. Happy woodworking, and may your finishes always turn out beautifully!