Do You Use Steel Wool After Polyurethane Finish? Essential Guide

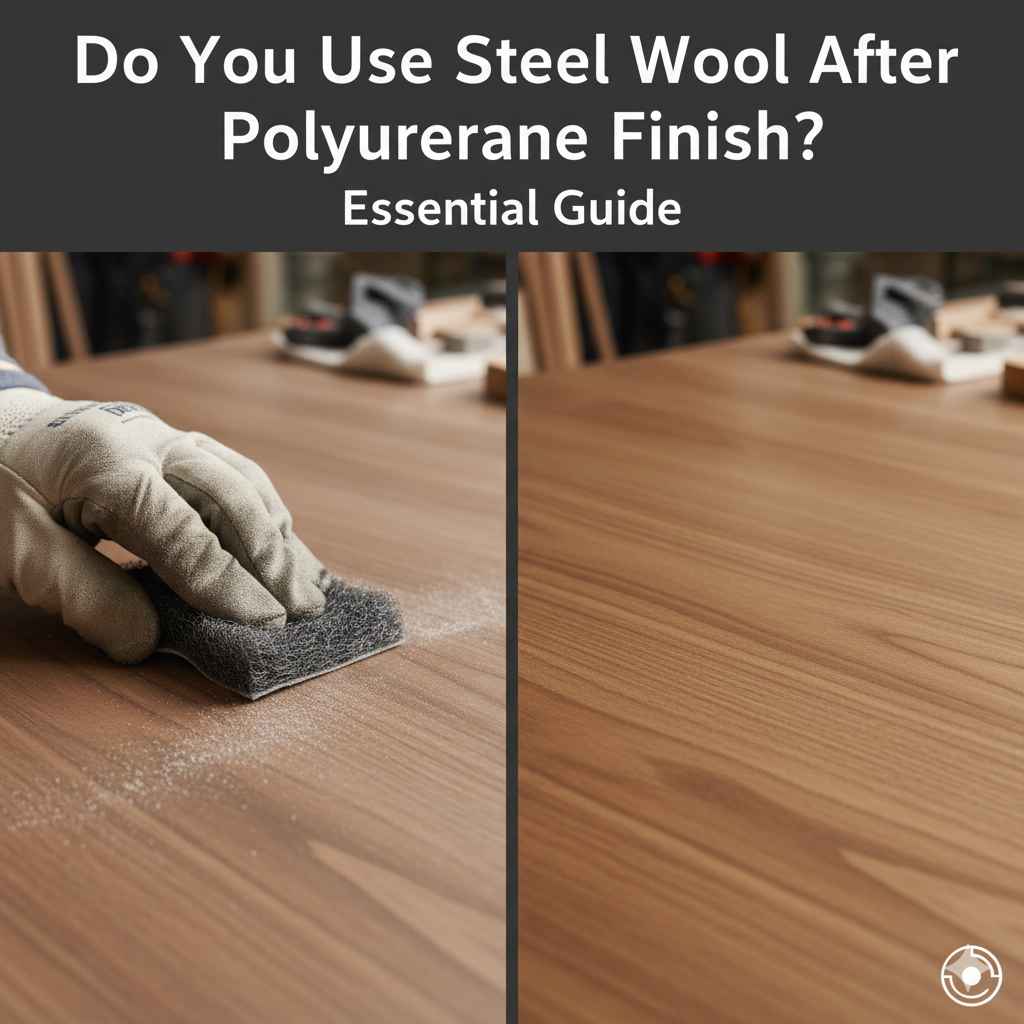

Yes, you absolutely can and often should use steel wool after applying a polyurethane finish, but only at specific stages and with the right grit! It’s a crucial step for achieving a smooth, professional-looking finish on your woodworking projects. Using steel wool correctly helps to level out imperfections and prepare the surface for subsequent coats or the final buffing.

Hey there, fellow woodworkers! Ever stare at a piece of furniture you’ve just finished with polyurethane and notice tiny bumps, dust specks, or just a general lack of that silky-smooth feel? You’re not alone! Many beginners get a little stumped when it comes to the final stages of finishing. It’s a common question: “Do I use steel wool after polyurethane?” It can seem a bit counterintuitive to sand a finished surface, can’t it? But trust me, when done right, it’s a game-changer. This guide will walk you through exactly when and how to use steel wool to get that gorgeous, professional finish you’ve been dreaming of. Let’s make your projects shine!

The Big Question: Steel Wool After Polyurethane? Let’s Unpack It

It’s a question that pops up a lot in workshops and online forums: “Do you use steel wool after polyurethane finish?” The short answer is a resounding yes, but with some very important caveats. Polyurethane is a fantastic protective coating, known for its durability and resistance to water and chemicals. However, applying it isn’t always as simple as brushing it on and calling it a day. Very rarely is a finish perfectly smooth right after application. Dust particles can settle, tiny bubbles might form, or brush strokes can leave slight textures.

This is where steel wool comes into play. It acts as a very fine abrasive that can gently level out these minor imperfections between coats of polyurethane, or even as a final step before waxing or buffing. When used correctly, it doesn’t scratch your finish; instead, it smooths it out, preparing it for the next layer or for direct use. Think of it like a gentle spa treatment for your wood finish!

Why Use Steel Wool? The Benefits of a Smooth Finish

Using fine-grade steel wool between coats of polyurethane offers several significant advantages:

- Levels Minor Imperfections: Even in a dust-free environment, microscopic particles and slight variations can occur. Steel wool gently removes high spots and imperfections, creating a flatter surface.

- Enhances Adhesion: A slightly abraded surface creates better “tooth” for the next coat of polyurethane to adhere to, ensuring a stronger, more durable finish.

- Removes “Orange Peel” Effect: Sometimes, polyurethane can dry with a texture resembling an orange peel. Fine steel wool can knock down these high spots for a smoother look.

- Prepares for Final Buffing/Waxing: For a truly glass-like finish, steel wool helps create the ideal foundation for rubbing compounds, waxes, or polishes.

- Achieves Louvered Surfaces: For surfaces that will be handled a lot, like table tops or chairs, a buttery-smooth finish is essential for comfort and aesthetics. Steel wool is key to this.

When to Use Steel Wool: Timing is Everything

This is perhaps the most critical aspect. You don’t just go at your polyurethane with steel wool anytime you please! The timing makes all the difference between smoothing and ruining your finish. Here’s the breakdown:

Between Coats of Polyurethane

This is the primary time you’ll be reaching for your steel wool. After each coat of polyurethane has thoroughly dried (and I mean really dried – check your product’s recommendations), you’ll use your steel wool to lightly abrade the surface.

- Allow for Complete Curing: It’s crucial that the polyurethane is dry to the touch and has had ample time to cure enough not to gum up the steel wool or peel off. This usually means waiting at least 4-24 hours between coats, depending on the type of polyurethane and humidity.

- Gentle Abrasion: The goal here is not to remove the finish, but to lightly scuff the surface. Think of it as creating a smooth, even base for the next coat to bond to.

- Clean Thoroughly: After “sanding” with steel wool, you MUST thoroughly remove all dust. A tack cloth is ideal for this, ensuring no abrasive particles interfere with the next wet coat.

As a Final Step (Before Waxing/Buffing)

Once you’ve applied your final coat of polyurethane and it has dried and cured sufficiently (this might be several days or even a week, depending on the product), you can use steel wool as a final polishing step.

- Ultra-Fine Grits: For this stage, you’ll want the finest grits available (0000 or maybe 000). This removes any microscopic dust motes or faint haziness without dulling the sheen too much.

- Lubrication is Key: It’s often recommended to use a lubricant, like mineral spirits, a bit of wax, or a dedicated polishing compound, when using steel wool for final polishing. This helps the steel wool glide smoothly and prevents excessive dulling.

- Buffing After: After using steel wool for final polishing, you’ll typically follow up with a clean cloth or specialized buffing tool to bring out the shine.

When NOT to Use Steel Wool

Avoid steel wool:

- On a wet or uncured finish.

- Aggressively – you are not trying to strip the finish.

- With very coarse grits – this will do irreversible damage.

- If your polyurethane is a “rub-on” type that cures very thin and might be too delicate for any abrasion. Always test!

Choosing the Right Steel Wool: Grit Matters!

Not all steel wool is created equal, and using the wrong grit can be disastrous. For use with polyurethane finishes, you should only be using the finest grades. Anything coarser will essentially sand away your finish or leave deep scratches that you’ll then have to fix.

Here’s a quick guide to common steel wool grades:

| Grade | Description | Typical Use with Polyurethane |

|---|---|---|

| Coarse (0, 1) | Rough, for heavy-duty cleaning and stripping paint. | NEVER use with polyurethane finishes. |

| Medium (2) | For removing rust and moderate deburring. | NEVER use with polyurethane finishes. |

| Fine (3) | General cleaning, scuffing before painting. | Occasionally used for between-coat sanding if very light surface issues exist, but not ideal. |

| Super Fine (00, 000) | Light cleaning, polishing, and smoothing delicate surfaces. | IDEAL for between-coat sanding and final polishing. |

| Ultra Fine (0000) | For the finest polishing, buffing metal, and achieving mirror finishes. | BEST OPTION for final touch-ups and achieving a very smooth surface before waxing or buffing. |

For working with polyurethane, you’ll primarily be looking for 0000 grade (super fine). For exceptionally smooth finishes, 0000 grade is often the go-to. These grades are fine enough to gently abrade the surface and remove minor imperfections without leaving noticeable scratches.

Step-by-Step: How to Use Steel Wool After Polyurethane

Ready to put this knowledge into practice? Here’s a simple, step-by-step guide assuming you’re working between coats of polyurethane:

What You’ll Need:

- Appropriate grade steel wool (typically 0000)

- Tack cloth

- Clean, lint-free cloths

- Mineral spirits (optional, for greasing the wool)

- Your dried polyurethane-coated project

The Process:

- Ensure the Polyurethane is Dry: This is paramount. Feel the surface; it should be hard and completely dry to the touch, with no tackiness. Check the manufacturer’s guidelines for recommended drying times between coats.

- Prepare Your Steel Wool: Take a pad or a piece of your 0000 steel wool. To minimize dust and achieve a smoother action, you can lightly grease the wool. Dip it briefly into a small amount of mineral spirits, or rub a bit of paste wax onto it. Wring out any excess. This helps it glide better and traps dust.

- Lightly Sand the Surface: With long, even strokes, gently rub the greased steel wool over the entire surface of your project. Go with the grain of the wood. Apply only light, consistent pressure. You are not trying to remove the finish; you are simply “de-nibbing” or smoothing out any tiny imperfections. If you hear a rough, hissing sound, you may be pressing too hard, or the finish isn’t dry enough.

- Work in Sections: For larger projects, work in manageable sections so you can clean them before the dust settles.

- Clean Off Debris Thoroughly: This is SUPER important. Use a clean, dry, lint-free cloth to wipe away all the steel wool dust and any loose particles. Then, use a tack cloth. A tack cloth is specifically designed to pick up fine dust from surfaces. Lightly drag the tack cloth over the surface; don’t press down hard. You want it to pick up all the shiny or dusty bits left behind. Repeat if necessary until the surface is perfectly clean and smooth to the touch.

- Inspect Your Work: Run your hand over the surface. It should feel significantly smoother. Check for any missed dust or debris.

- Apply the Next Coat: Once you are absolutely sure the surface is clean and dust-free, you can proceed with applying your next coat of polyurethane according to the manufacturer’s instructions.

For Final Polishing: If you are doing this after the final coat, the steps are similar, but the pressure might be even lighter, and the goal is to achieve a soft sheen. You’d likely use a product like a rubbing compound with the 0000 steel wool, followed by a fine wax or polish, and then a final buffing with a soft cloth.

Alternatives to Steel Wool

While steel wool (specifically 0000 grade) is a favorite among many woodworkers for its effectiveness and cost-efficiency, there are alternatives if you prefer not to use it or can’t find it:

Synthetic Scouring Pads

These are made from non-woven nylon or polyester fibers impregnated with abrasives. They come in different grits, similar to sandpaper.

- Pros: They don’t rust like steel wool, are some are washable, and they can be less prone to leaving behind tiny metal fragments (though you still need to clean up dust). They are also very flexible.

- Cons: Can be more expensive than steel wool. Identifying the exact grit can sometimes be confusing.

- Best For: Between-coat sanding. Look for ones labeled “extra fine” or “ultra fine.”

Very Fine Grit Sandpaper

You can use ultra-fine grit sandpaper, such as 400-grit, 600-grit, or even finer, for between-coat sanding.

- Pros: Widely available, familiar to most DIYers.

- Cons: Sandpaper can clog up quickly with polyurethane dust. It’s crucial to use a light touch, as it’s easier to scratch the finish or sand through it if you’re not careful. It’s less forgiving than steel wool for this specific application.

- Best For: Between-coat sanding, especially if you are very careful.

Polishing Compounds

These are often used as the final step on a cured finish, sometimes in conjunction with 0000 steel wool or a soft pad.

- Pros: Specifically designed for smoothing and polishing finishes to a high sheen. Often available in different stages of abrasion.

- Cons: Can be more expensive. Usually intended for the very final stages, not necessarily between multiple coats.

- Best For: Final smoothing and achieving a high-gloss finish.

The choice often comes down to personal preference and the specific look you’re trying to achieve. However, for a beginner looking for a reliable and cost-effective method for between-coat smoothing and polishing, 0000 steel wool remains a top recommendation.

Safety First! Working with Steel Wool and Polyurethane

While we’re talking about smoothing and finishing, a quick word on safety is always a good idea. Woodworking involves different materials, and it’s important to stay safe.

- Ventilation: Always work in a well-ventilated area when applying polyurethane and when working with mineral spirits. Fumes can be harmful. Consider wearing a respirator certified for organic vapors. You can find guidance on choosing appropriate respiratory protection from organizations like the Occupational Safety and Health Administration (OSHA), for instance, their Respiratory Protection Standard provides detailed information.

- Gloves: Wearing nitrile gloves is a good idea to protect your skin from the polyurethane and mineral spirits.

- Eye Protection: Always wear safety glasses. Tiny particles can fly unexpectedly, even from fine steel wool.

- Fire Hazard: Steel wool, especially when used with mineral spirits or oils, can spontaneously combust when it oxidizes. It’s the same risk as oily rags. Ensure you dispose of used steel wool properly. Don’t just wad it up and throw it in the trash. Soak it in water in a metal container with a lid or let it dry completely outdoors away from any flammable materials before disposal. Check your local fire department or waste management guidelines for proper disposal procedures.

- Dust Control: Even fine steel wool creates fine dust. Ensure you clean up thoroughly to avoid inhaling it or having it contaminate your finishes.

Frequently Asked Questions (FAQ)

Here are some common questions beginners have about using steel wool with polyurethane:

Q1: Can I use steel wool on oil-based polyurethane?

A: Yes, you can use steel wool (typically 0000 grade) on oil-based polyurethane between coats, just as you would with water-based. Ensure each coat is fully dry and cured enough to withstand the light abrasion. The principles of gentleness and thorough cleaning apply here too.

Q2: Will steel wool make my finish dull?

A: If you use a grit that is too coarse, or if you sand too aggressively, yes, it can dull or even scratch your finish. However, using the recommended 0000 grade lightly between coats is intended to create a surface that the next coat adheres to better and ultimately dries smoother. For final polishing, 0000 steel wool can help achieve a satin or matte look, or it can be used with polishing compounds and waxes to bring out a high gloss.

Q3: How long do I need to wait between steel wooling and applying the next coat?

A: You can apply the next coat immediately after you’ve thoroughly cleaned the surface and confirmed it’s dust-free. The steel wool step is done after the previous coat has dried and cured sufficiently. The critical factor is cleanliness after steel wooling.

Q4: What’s the difference between steel wool and sandpaper for this job?

A: Steel wool (especially 0000 grade) is composed of very fine, flexible strands that conform to the surface. This often leads to a more consistent, gentle abrasion compared to the relatively stiff grit on sandpaper. Sandpaper can sometimes scratch or create deeper gouges if not used extremely carefully. Steel wool is generally more forgiving for this specific purpose of light de-nibbing between polyurethane coats. Sandpaper can also clog faster with the sticky polyurethane residue.

Q5: Can I use a power sander with steel wool?

A: No, you should never use steel wool with a power tool like a random orbital sander. Steel wool is meant for hand-application only, with very light pressure. Power sanding with steel wool would be far too aggressive and would destroy your finish.

Q6: What if I can’t find 0000 steel wool?

A: If 0000 is unavailable, look for the finest synthetic scouring pads or consider using very fine grit sandpaper (like 600-grit or higher) with extreme caution and very light pressure. However, 0000 steel wool is the industry standard for this application, so it’s worth finding if possible. You might find it at hardware stores, woodworking supply shops, or online retailers.