Air Saw Blades: Essential Guide

Choosing the right air saw blade is crucial for successful cutting. This guide simplifies understanding air saw blade types, materials, and teeth per inch (TPI) to help you pick the perfect blade for any job, ensuring clean cuts and efficient work.

Hey there, fellow DIYers and aspiring woodworkers! Md Meraj here. Ever looked at that trusty air saw and wondered, “What’s the deal with all these different blades?” It’s a super common puzzle when you’re starting out. Trying to cut through metal, plastic, or even tough wood without the right air saw blade can be frustrating, leading to messy cuts or even damaging your tool. But don’t worry, it’s not as complicated as it seems! I’m here to guide you through the wonderful world of air saw blades, making sure you have the confidence to pick the exact blade you need for your next project. We’ll break down what makes each blade unique and how to match them to your materials. Get ready to make those cuts with ease and precision!

Understanding Your Air Saw Blades: A Beginner’s Blueprint

An air saw, also known as a pneumatic reciprocating saw, is a fantastic tool for cutting various materials. But the real magic happens with the blade. It’s the part that directly interacts with your material, and its design dictates what it can cut, how well it cuts, and how long it lasts. Think of it like having the right paintbrush for the right painting; the air saw is the artist, and the blade is the brush. Choosing the wrong blade is like trying to paint a landscape with a tiny detail brush – it’ll be a struggle, and the result won’t be what you envisioned.

In this guide, we’ll demystify air saw blades. We’ll cover what to look for, how different designs work, and when to use each type. By the end, you’ll be a pro at selecting the best air saw blade for any task, saving you time, effort, and a whole lot of frustration. Let’s get those blades sorted!

Key Components of an Air Saw Blade

Before we dive into blade types, it’s helpful to understand the basic anatomy of an air saw blade. These components influence its performance:

- The Blade Body: This is the main part of the blade, usually made of metal. Its thickness and flexibility play a role in how it cuts and how durable it is.

- The Teeth: These are the business end of the blade, designed to bite into and cut through materials. Their shape, size, and spacing are critical.

- The Shank: This is the part of the blade that inserts into your air saw. Most air saws use a universal shank, but it’s always good to check your tool’s manual.

- The TPI (Teeth Per Inch): This number tells you how many teeth are on one inch of the blade. It’s a huge factor in determining what material the blade is best suited for and the type of cut you’ll get.

Material Matters: What Are Air Saw Blades Made Of?

The material an air saw blade is made from has a direct impact on its durability and cutting ability, especially when dealing with tougher substances. Here are the most common materials you’ll encounter:

High-Speed Steel (HSS)

HSS blades are a very popular choice for a reason. They offer a great balance of strength and heat resistance, making them effective for cutting through a range of metals and wood. They can handle moderate workloads without becoming dull too quickly. For general-purpose cutting of softer metals and wood, HSS is a reliable go-to.

Bi-Metal

Bi-metal blades are a step up in durability and performance, especially for metal cutting. They have a high-speed steel cutting edge that is electron-beam welded to a flexible spring steel back. This combination provides the best of both worlds: the hardness of HSS for cutting and the flexibility of spring steel to prevent shattering. They are excellent for cutting through various metals, including steel, aluminum, and copper, and can also handle wood quite well. Bi-metal blades tend to last longer than standard HSS blades.

Carbide-Tipped

These are the heavy-hitters for cutting extremely hard materials. Carbide is an exceptionally hard material, much harder than HSS. Carbide-tipped blades have teeth made of carbide brazed onto a steel body. They are perfect for aggressive cutting through thick metals, cast iron, tile, concrete, and even fiberglass. While they are excellent for tough jobs, they are also typically more expensive and less flexible than HSS or bi-metal blades.

Tungsten Carbide Grit

Instead of distinct teeth, these blades have a coating of tungsten carbide grit along the cutting edge. They don’t “cut” in the traditional sense but rather “grind” away material. These are specialized blades, excellent for cutting brittle materials that traditional teeth might chip or break, such as tile, glass, ceramic, and hard plastics. They are also good for abrasive materials.

| Blade Material | Best For | Pros | Cons |

|---|---|---|---|

| High-Speed Steel (HSS) | Wood, plastics, softer metals (aluminum, copper) | Good balance of hardness & heat resistance, affordable | Can wear faster on hard materials, less flexible |

| Bi-Metal | Various metals (steel, aluminum), wood, plastics | Durable, flexible, long-lasting, good for tough jobs | More expensive than HSS |

| Carbide-Tipped | Thick metals, cast iron, tile, concrete, fiberglass | Extremely hard, aggressive cutting, very durable | Expensive, less flexible, can be brittle if mishandled |

| Tungsten Carbide Grit | Tile, glass, ceramic, stone, hard plastics, abrasive materials | Grinds rather than cuts (good for brittle stuff), durable for its purpose | Slow cutting, not for wood or metal, can wear down |

Understanding TPI: The Secret to a Clean Cut

Teeth Per Inch, or TPI, is one of the most critical specifications on any saw blade, including those for your air saw. It directly influences the speed of your cut and the quality of the finish. Generally, higher TPI means finer teeth, and lower TPI means coarser teeth.

High TPI (e.g., 18 TPI and above)

Blades with a higher TPI have more teeth packed into each inch. This means more teeth are in contact with the material at any given time.

- What it’s good for: High TPI blades are your best friends for cutting thin materials and achieving a smooth, clean finish. They’re ideal for sheet metal, thin-walled pipes, hardwoods, and plastics where you want to avoid splintering or burrs.

- The tradeoff: Because there are so many small teeth, they remove material more slowly. So, while the cut is clean, it won’t be the fastest.

Medium TPI (e.g., 10-18 TPI)

These blades offer a good compromise between cutting speed and finish quality. They are excellent for general-purpose cutting tasks.

- What it’s good for: Medium TPI blades are versatile. They are great for cutting thicker metals, general construction lumber, and some plastics. If you’re not sure what TPI to choose for a mixed bag of materials, a medium TPI blade is often a safe bet.

Low TPI (e.g., 6-10 TPI)

With fewer, larger teeth in each inch, low TPI blades are designed for aggressive, fast cutting.

- What it’s good for: These are the blades you reach for when speed is the priority and a rougher cut is acceptable. They excel at cutting thick, soft materials like thicker lumber, PVC pipes, and some softer metals where you need to power through the material quickly.

- The tradeoff: They can cause rougher cuts, more splintering in wood, and more material breakdown, especially in thinner or harder materials.

Remember, it’s often stated that you should have at least two teeth in contact with the material you’re cutting for optimal performance and blade life. This rule of thumb helps guide your TPI selection.

Blade Tooth Shape and Set: The Finer Details

Beyond TPI and material, the actual shape of the teeth and how they are arranged (the “set”) also matters. While this can get technical quickly, understanding the basics can help:

- Standard (Straight) Teeth: These are uniform and suitable for general cutting.

- Hook Teeth: These teeth have a more aggressive, pointed shape that bites into material easily, making them great for fast cutting of wood.

- Milled Teeth: These are precision-ground teeth that offer a cleaner cut, especially in metals.

- Side-Set Teeth: The teeth are bent alternately to the left and right of the blade body. This creates a wider kerf (the width of the cut), which helps prevent the blade from binding and clears debris more effectively, often resulting in faster cuts.

- Waved-Set Teeth: The teeth are set in small, undulating waves. This is ideal for cutting thin metal and tubing because it distributes the cutting force over a larger area, reducing heat and preventing teeth from breaking.

Matching the Blade to Your Material: A Practical Guide

This is where it all comes together! Knowing your material is half the battle. Here’s a quick reference to help you choose the right air saw blade:

For Woodworking Projects

When cutting wood, consider the type and thickness. Thicker hardwoods might require a lower TPI for faster removal, while fine woodworking or cutting plywood might call for a higher TPI to prevent splintering.

- Softwoods (Pine, Fir): Medium to Low TPI (6-10 TPI) with a hook or standard tooth.

- Hardwoods (Oak, Maple): Medium TPI (8-14 TPI) with a hook or standard tooth for general cuts. High TPI (18-24 TPI) for cleaner, finer cuts.

- Plywood & Laminates: High TPI (18-24 TPI) with standard teeth to minimize chipping and splintering.

- Demolition/Rough Cuts: Low TPI (6-8 TPI) with aggressive teeth for speed.

For Metal Fabrication and Repair

Cutting metal requires durable blades that can withstand heat and abrasion. Bi-metal blades are usually the top choice here.

- Thin Sheet Metal (up to 1/8″): High TPI (18-24 TPI) with waved-set teeth to prevent overheating and binding. Bi-metal is excellent.

- Medium Thickness Metal (1/8″ – 1/4″): Medium TPI (10-18 TPI) with standard or side-set teeth. Bi-metal is highly recommended.

- Thick Metal (over 1/4″), Steel, Cast Iron: Low to Medium TPI (6-10 TPI) with robust teeth. Carbide-tipped blades are often best for very thick or hard metals.

- Aluminum & Copper: Medium TPI (10-14 TPI) with standard teeth. Bi-metal or even HSS can work well.

For Plastics and Composites

Plastics, especially acrylics, can melt if cut too aggressively or with the wrong blade, leading to a gummy mess. Composites can be abrasive.

- General Plastics (PVC, ABS): Medium TPI (10-14 TPI) with standard teeth.

- Acrylics & Plexiglass: High TPI (18-24 TPI) with fine teeth to prevent cracking and melting. Keep speeds moderate.

- Fiberglass & Composites: Specialized abrasive blades or carbide-tipped blades are often necessary due to the material’s hardness and tendency to clog.

For Demolition and General Purpose Use

When you just need to cut something up quickly without worrying too much about a pristine finish, speed is key.

- Demolition: Low TPI (6-8 TPI) with aggressive, durable teeth. Look for blades marketed as “demolition” blades, as they are designed to be tough and cut through a variety of mixed materials.

- General Purpose: A medium TPI (10-14 TPI) bi-metal blade is a great all-rounder for occasional use across different materials.

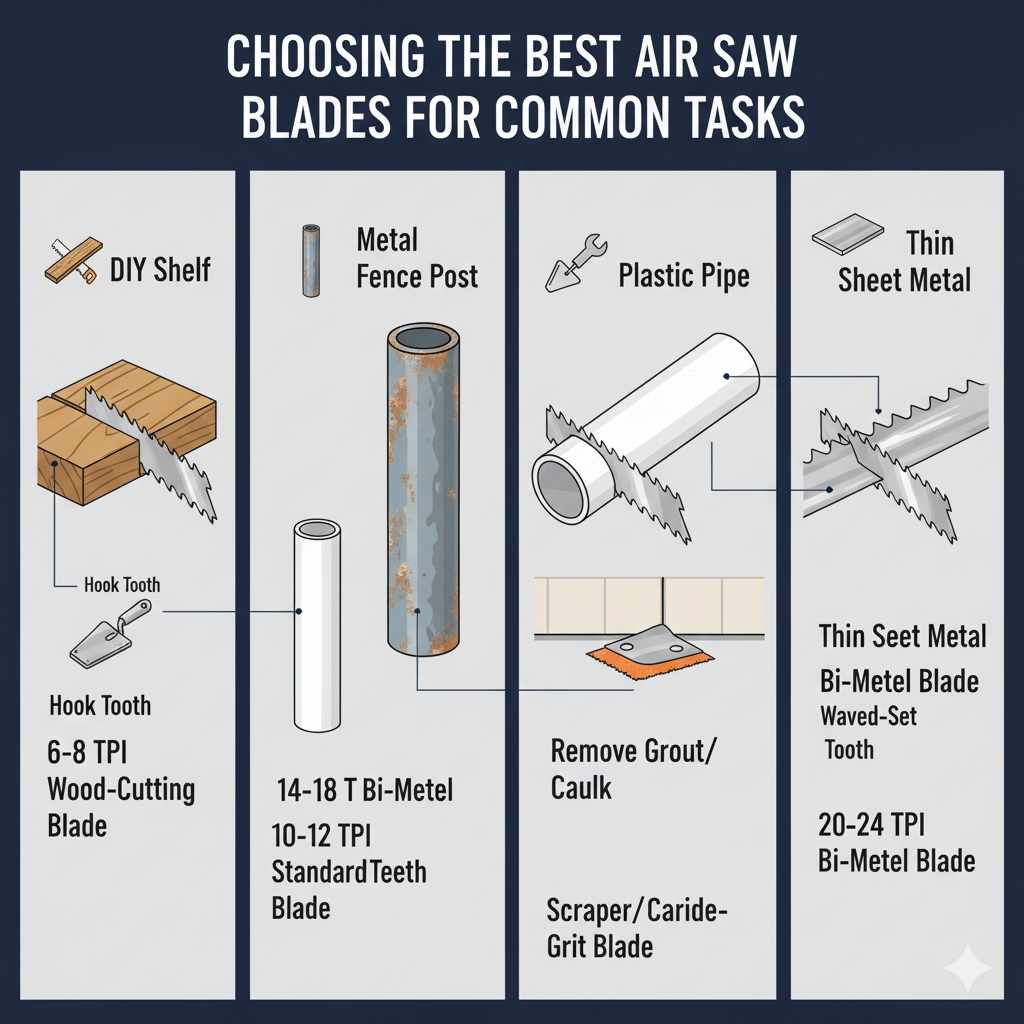

Choosing the Best Air Saw Blades for Common Tasks

Let’s put this knowledge into action:

- Cutting a 2×4 for a DIY shelf: You’ll want to cut through wood quickly and cleanly. A 6-8 TPI wood-cutting blade with a hook tooth design will do the job efficiently. If you want a slightly cleaner edge, a 10 TPI blade would also work well.

- Trimming a metal fence post: This is a common repair task. A bi-metal blade with 14-18 TPI is ideal. The bi-metal construction handles metal well, and the medium TPI offers a good balance between speed and finish.

- Cutting through a plastic pipe during a renovation: For PVC or ABS pipes, a 10-12 TPI blade with standard teeth is perfect. It will cut smoothly without melting or cracking the plastic.

- Removing old caulk or grout: For this, you don’t usually need a standard toothed blade. Specialized scraper or carbide-grit blades are designed for these tasks, offering an abrasive edge to grind away soft or brittle materials.

- Cutting through thin sheet metal for a craft project: You’ll want a fine finish here. A high TPI (20-24 TPI) bi-metal blade with a waved-set tooth pattern will provide the cleanest cut and prevent the thin metal from getting mangled.

Tips for Maximizing Air Saw Blade Performance and Life

Even with the right blade, how you use it matters! Here are some tips from my workshop:

- Let the Tool Do the Work: Don’t force the air saw. Apply steady, even pressure. Forcing can overheat the blade, increase wear, and lead to breakage.

- Clamp Your Material: Always secure your workpiece. Loose material can vibrate, leading to inaccurate cuts and potential safety hazards. Check out resources like OSHA’s general safety and health provisions for workplace safety best practices, which include securing materials.

- Maintain Proper Tool Speed: Some air saws have variable speed. Use a slower speed for harder materials or when precision is key, and faster speeds for softer materials and quicker cuts.

- Keep Blades Clean: After use, especially with metal, clean any residue or build-up from the teeth. This ensures optimal cutting performance next time.

- Store Blades Properly: Keep your blades in their original packaging or a blade organizer to prevent damage to the teeth.

- Rotate Blades: If a blade starts to feel dull or cut slower, don’t push it. Switch to a fresh one. Replacing blades proactively is much safer and more efficient than struggling with a dull blade.

- Lubricate (if applicable): Some air saws benefit from a few drops of air tool oil in the air inlet before use to keep the internal mechanisms running smoothly, which in turn helps the tool perform optimally with the blade.

Frequently Asked Questions (FAQ)

What is the most common type of air saw blade?

The most common and versatile type is the bi-metal blade. It offers a great balance of durability and cutting ability for a wide range of materials, from wood to various metals, making it a reliable choice for many DIY tasks.

Can I use a wood blade to cut metal?

Generally, no. Wood blades have fewer teeth per inch (TPI) and are designed for wood. Using them on metal can lead to dulling, breakage, and a very poor cut. Always use blades specifically designed for metal when cutting metal.

How often should I replace my air saw blade?

There’s no set schedule, as it depends on the material you’re cutting and how often you use the saw. You should replace a blade when you notice a significant decrease in cutting speed, increased effort required to cut, or rougher-than-usual cut quality. It’s always better to replace a blade too soon than too late for safety and efficiency.